锡铅钎料钎焊时应采用磷酸水溶液钎剂(见表3-51);铅钎料钎焊时采用氯化锌水溶液钎剂;镉钎料钎焊时用QJ205钎剂;BAg40CuZnCdNi和BAg45CdZnCu钎料钎焊时用FB102或FB103钎剂;其他银钎料、铜磷和铜磷银钎料钎焊时用FB102钎剂。炉中钎焊建议在保护气氛下进行,并采用FB104钎剂。

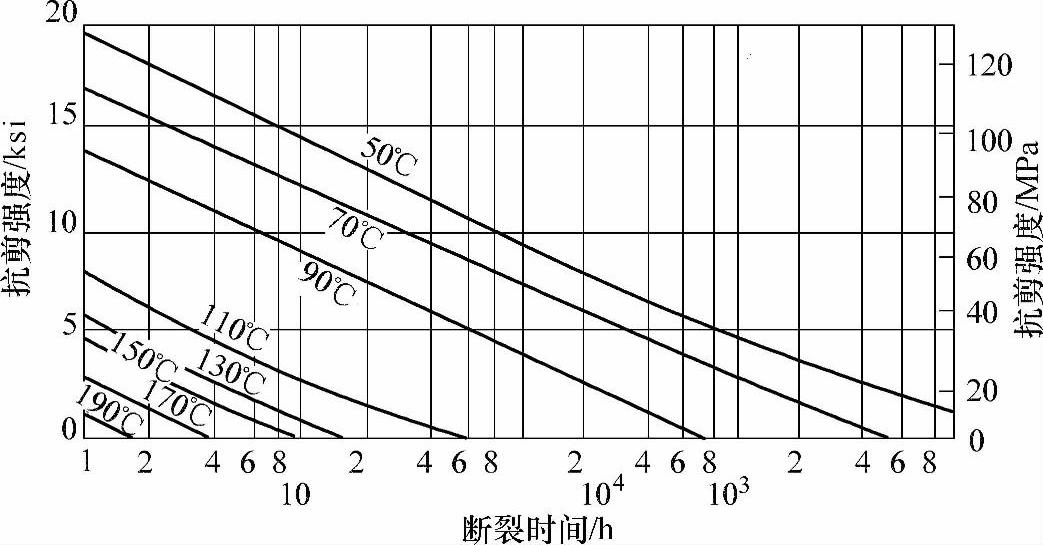

图3-81 95Sn-5Ag钎料钎焊的黄铜搭接接头在不同温度下的应力-断裂时间曲线 Fig.3-81 Stress-time to failure curves at various temperatures for overlap joints between brass components soldered with 95Sn-5Ag

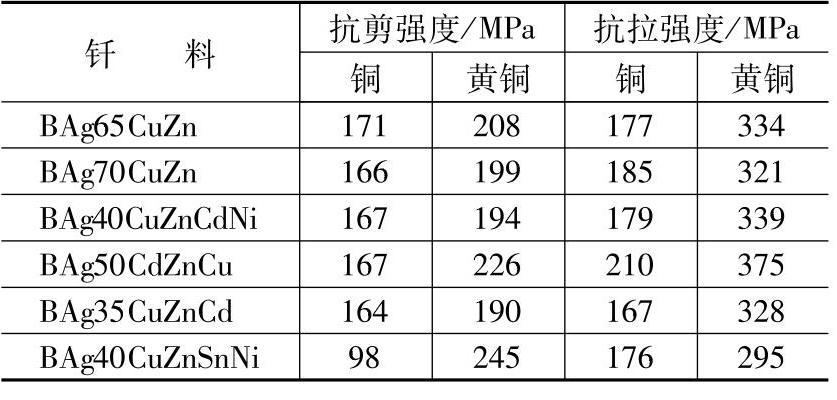

表3-60 用银钎料钎焊的铜和黄铜接头的强度Table 3-60 The strengths of copper and brass joints brazed with various silver base filler metals

(续)

(https://www.xing528.com)

(https://www.xing528.com)

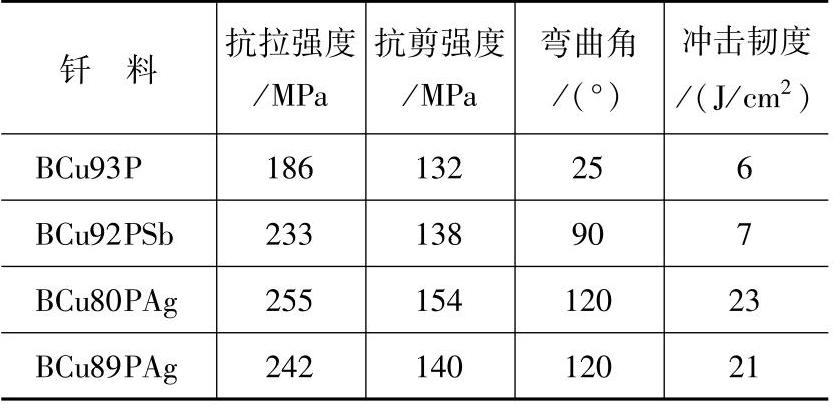

表3-61 用铜磷和铜磷银钎料钎焊的铜接头的力学性能Table 3-61 The mechanical properties of copper joints brazed with copper-phosphorus and copper-phoshorus-silver filler metals

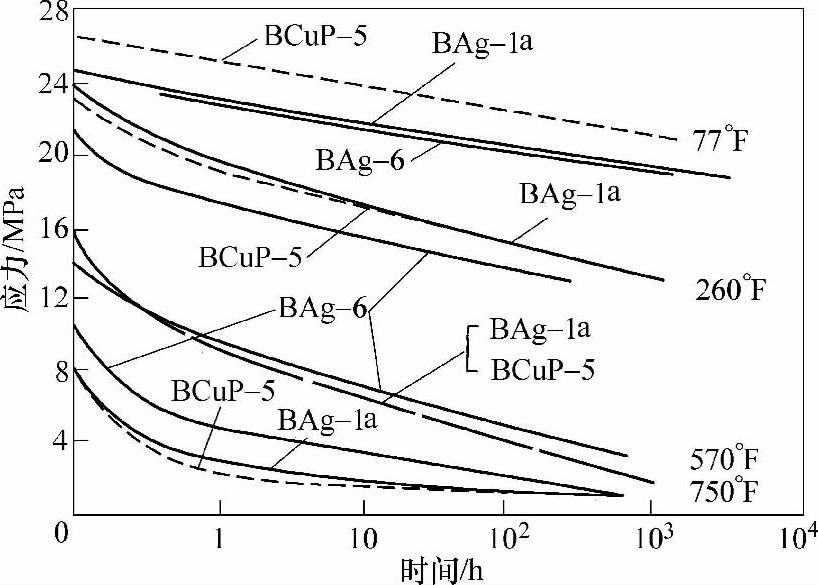

图3-82 铜接头的应力-时间破坏曲线(1℉=5/9℃) Fig.3-82 Stress-time to failure curves of copper joints

注:BAg-1a相当于BAg50CdZnCu,BCuP-5相当于BCu80PAg,BAg-6相当于BAg50CuZn。

免责声明:以上内容源自网络,版权归原作者所有,如有侵犯您的原创版权请告知,我们将尽快删除相关内容。